1. Introduction:

The world of cuisine has witnessed remarkable transformations over centuries, with innovations continuously reshaping how we produce, distribute, and consume food.

Among the most profound revolutions is the evolution of the meat industry, propelled by ingenious inventions that have forever altered the landscape of meat processing and consumption.

In this blog, we will delve into the question of which invention was most important in revolutionizing the meat industry, and having a pivotal role. Through a lens of historical context with an economic impact, we aim to unravel the threads of innovation that have woven the fabric of the modern meat industry.

The blog delved into the question of which invention was most important in revolutionizing the meat industry.

2. Invention No 1 – Refrigeration technology:

Refrigeration technology stands as the cornerstone of the modern meat industry, reshaping every facet of food production. Prior to its advent, meat preservation relied on crude methods like salt curing and ice storage, limiting both shelf life and geographic reach.

However, refrigeration’s introduction revolutionized the industry by significantly extending the freshness of meat and reducing spoilage rates through controlled cooling.

This innovation not only facilitated global distribution but also lowered costs associated with preservation and transportation, making meat more accessible and affordable to a broader consumer base.

Read More: Can You Freeze Marinated Meat?

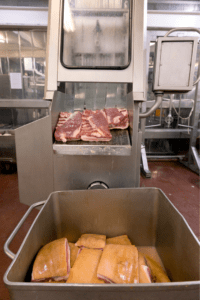

3. Invention No 2 – Meat packing plants and assembly lines:

Meat packing plants and assembly lines represent a transformative innovation that revolutionized the meat industry’s efficiency and scale of production. Originating in the late 19th and early 20th centuries, these systems introduced mechanized processes. This included slaughtering, processing, and packaging meat products, replacing labor-intensive manual methods.

By integrating conveyor belts, specialized machinery, and standardized procedures, assembly line techniques streamlined every stage of meat processing. These significantly increased output while reducing labor costs and production time.

This innovation led to the establishment of large-scale meatpacking facilities in urban centers, where economies of scale could be leveraged to meet the growing demand for meat products.

Despite concerns regarding worker conditions and animal welfare, meat packing plants and assembly lines remain integral to the modern meat industry. Thus driving efficiency, productivity, and standardization in meat processing operations worldwide.

4. Invention No 3 – Vacuum packaging:

Vacuum packaging stands as a pivotal innovation in the meat industry, offering a highly effective method for preserving freshness and extending shelf life. This technique involves the removal of air from the packaging before sealing, creating a vacuum environment that inhibits microbial growth and oxidative reactions.

By eliminating oxygen, vacuum packaging helps maintain the quality, texture, and flavor of meat products. The absence of air also prevents freezer burn and dehydration. Thus further enhancing the product’s overall appeal and consumer satisfaction.

Vacuum-sealed packaging not only extends the storage life of meat products but also facilitates efficient transportation and distribution. It also helps in minimizing food waste and maximizing profitability for producers and retailers alike.

Moreover, advancements in packaging materials and equipment have led to increased reliability, durability, and efficiency in vacuum packaging operations. Making it an indispensable tool for ensuring food safety and quality in the modern meat industry.

Read More: How to Preserve Meat Without Refrigeration? 10 Practical Steps

5. Invention No 4 – Synthetic Meat Production:

Synthetic meat production represents a revolutionary advancement in the meat industry, offering a sustainable and ethical alternative to traditional livestock farming. Also known as cultured meat or lab-grown meat, this innovative technology involves growing meat from animal cells in a controlled laboratory environment, bypassing the need for raising and slaughtering animals.

By harnessing biotechnology and tissue engineering techniques, synthetic meat production promises to address critical issues. These includes such as environmental degradation, animal welfare concerns, and global food security challenges.

Furthermore, synthetic meat production has the potential to reduce the carbon footprint associated with traditional livestock farming.

While still in its early stages, ongoing research and development efforts aim to scale up production, improve taste and texture, and enhance cost-effectiveness to make synthetic meat a viable and mainstream option for consumers worldwide.

6. Invention No 4 – Slaughtering innovations:

Slaughtering innovations encompass a range of advancements in techniques and practices aimed at improving the efficiency and sustainability of the meat industry.

Key advancements include the introduction of stunning techniques to render animals unconscious before slaughter. Additionally, the implementation of automated slaughtering systems and carcass processing technologies enhances efficiency and consistency.

Moreover, advancements in resource efficiency and waste reduction strategies have addressed environmental concerns associated with meat production. These innovations have indeed significantly transformed the industry. However, ongoing efforts are necessary to ensure that slaughtering practices continue to align with ethical, social, and environmental considerations. Thus promoting a more sustainable and responsible approach to meat production.

Read More: Can You Freeze Chicken Salad? Step by Step Guide

7. Comparison and Evaluation of All Five Inventions:

A. Impact on Preservation and Shelf Life Extension

- Refrigeration Technology:

- Enables preservation of meat by maintaining low temperatures, slowing bacterial growth, and extending shelf life.

- Provides consistent cooling to ensure freshness and quality.

- Meat Packing Plants and Assembly Lines:

- Streamline meat processing and packaging, optimizing efficiency and throughput.

- Help extend shelf life by reducing contamination risks and ensuring proper handling.

- Vacuum Packaging: Extends shelf life, inhibiting microbial growth while maintaining the quality and texture.

- Synthetic Meat Production: Offers potential for long-term preservation and shelf life without the need for refrigeration.

- Slaughtering innovations: Improve preservation and extend shelf life by enhancing efficiency, minimizing contamination risks, and ensuring proper handling practices.

B. Efficiency and Productivity

- Refrigeration Technology:

- Enables year-round availability and global distribution of meat products, increasing productivity.

- Requires energy consumption and infrastructure maintenance.

- Meat Packing Plants and Assembly Lines:

- Streamline production processes, reducing labor costs, and maximizing output.

- May raise concerns about worker conditions and ethical considerations.

- Vacuum Packaging:

- Improves efficiency by reducing food waste and maximizing profitability.

- Requires specialized equipment and materials for packaging.

- Synthetic Meat Production:

- Has the potential to optimize production processes and reduce environmental impact compared to traditional meat production.

- May require significant initial investment in research and development.

- Slaughtering innovations: Increase efficiency and productivity through automation however may include potential ethical concerns regarding animal welfare.

C. Environmental and Ethical Considerations

- Refrigeration Technology: Raises concerns about energy consumption and environmental impact.

- Meat Packing Plants and Assembly Lines: Raises ethical concerns about labor conditions and animal welfare.

- Vacuum Packaging:

- Reduces food waste and minimizes environmental impact.

- May raise concerns about packaging waste and material sustainability.

- Synthetic Meat Production:

- Offers potential for reduced environmental impact and improved animal welfare compared to traditional meat production.

- Raises ethical questions about the use of animal cells and biotechnology.

D. Future Prospects and Innovations

- Refrigeration Technology: Continues to evolve with advancements in energy efficiency and sustainable refrigerants.

- Meat Packing Plants and Assembly Lines: Adoption of technology-driven solutions to address labor concerns and optimize production processes.

- Vacuum Packaging: Advances in packaging materials and equipment to improve reliability and efficiency.

- Synthetic Meat Production: Ongoing research aims to scale up production, improve taste and texture, and enhance cost-effectiveness.

- Slaughtering innovations: Enhanced automation, AI integration, non-invasive stunning methods, sustainable practices, traceability, alternative protein sources, and continuous improvement in food safety.

8. Final Thoughts

In conclusion, the exploration of which invention was most important in revolutionizing the meat industry sheds light on the significant advancements that have shaped its evolution over time. While each invention has its unique strengths and challenges, their collective impact underscores the industry’s ability to adapt and thrive in response to evolving demands and technological advancements.

Looking ahead, continued innovation and collaboration will be essential in addressing emerging challenges such as sustainability and ethical considerations, ensuring a resilient and responsible future for the meat industry.